What Is a Plastic Sheet Bending Machine & How It Works (Industrial Guide for PP, HDPE & PVC Sheets)

- Share

- Issue Time

- Sep 30,2025

Summary

Discover how plastic sheet bending machines work for PP, HDPE, and PVC sheets. Learn applications, machine types, and benefits for industrial fabrication.

Introduction

In industrial plastic fabrication, bending thermoplastic sheets is a critical process for manufacturing tanks, ventilation systems, water treatment units, and custom plastic structures. A plastic sheet bending machine is the dedicated equipment that makes this possible, delivering precise angles, repeatable quality, and efficient production for PP, HDPE, and PVC sheets.

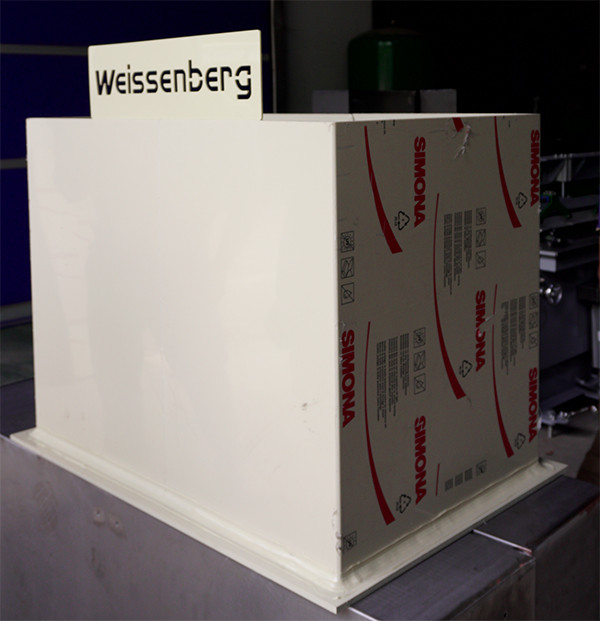

Weissenberg's WeiFlex Series bending machines are engineered for heavy-duty industrial applications, combining accurate heating, reliable clamping, and flexible configuration to achieve distortion-free bends.

What Is a Plastic Sheet Bending Machine?

A plastic sheet bending machine is designed to heat a narrow zone of a thermoplastic sheet until it becomes pliable, allowing it to be bent at a precise angle. Once cooled, the sheet retains the new shape permanently.

Unlike DIY strip heaters often used for acrylic, industrial machines like the WeiFlex Series support thicker sheets (3–25 mm or up to 35 mm depending on the model) and deliver consistent, crack-free results for PP, HDPE, and PVC.

How Does It Work?

1. Heating

Equipped with dual-zone heating: independent upper and lower heating elements for uniform heat distribution.

Optional V-shaped heating knives for partial melting and quick bending from 5° to 95°.

Optional flat heating knives for smooth surfaces with high aesthetic requirements.

2. Bending

High-density clamping ensures even pressure across the sheet.

Adjustable settings allow operators to adapt to different sheet thicknesses and materials.

3. Cooling

Sheets are held in place until cooled, ensuring the bend remains strong and stable.

Precise temperature control (±5°C) prevents defects like whitening, bubbles, or stress cracks.

Key Features of the WeiFlex Series

• High-Density Clamping – consistent pressure, no slip

• Dual-Zone Heating – uniform results for thicker sheets

• Material-Specific Settings – optimized bending pressure & temperature per plastic type

• Wide Thickness Range – supports sheets from 3–25 mm (up to 35 mm)

• Adjustable Angles – from 5° to 95°

• Precise Heating – temperature variation kept within ±5°C

Typical Applications

Plastic sheet bending machines are essential for:

• Pipeline and duct construction

• Ventilation systems

• Scrubbers & environmental equipment

• Swimming pools and aquaculture tanks

• Transport and logistics containers

Technical Data Snapshot (WeiFlex Series)

• Working Widths: 1500 mm to 6000 mm

• Bending Angles: 5° to 95°

• Sheet Thickness: 3–25 mm (up to 35 mm depending on model)

• Heating Options: V-shaped or flat heating knife

• Temperature Control: ±5°C precision

Why Choose an Industrial Plastic Sheet Bending Machine?

• Consistency: Repeatable bends across large-format sheets

• Efficiency: Faster production vs. manual heating methods

• Flexibility: Adjustable heating knives and PLC-controlled precision

• Durability: Designed for heavy-duty PP, HDPE, PVC fabrication

FAQ – Plastic Sheet Bending Machines

Q1. What materials can a PP sheet bending machine process?

Plastic sheet bending machines can process PP (polypropylene), HDPE (high-density polyethylene), PVC, and PVDF sheets. These materials are commonly used in chemical tanks, water treatment units, ventilation ducts, and marine structures.

Q2. What thickness range can the WeiFlex bending machines handle?

The WeiFlex Series supports sheets from 3 mm up to 25 mm as standard, and certain models allow bending of sheets up to 35 mm. This makes them ideal for both medium and heavy-duty industrial applications.

Q3. Why is dual-sided heating important for bending PP and HDPE sheets?

Thicker sheets like PP and HDPE require even heat distribution to avoid internal stress, whitening, or cracks. Dual-sided heating ensures the material softens uniformly, producing clean and distortion-free bends.

Q4. What are the main applications of the HDPE sheet bending machine?

Plastic sheet bending machines are widely used for:

• Chemical storage tanks and containers

Call to Action

An industrial plastic sheet bender is the cornerstone of industrial plastic fabrication, enabling manufacturers to build reliable PP, HDPE, and PVC tanks, pipelines, and custom structures with precision.

👉 Explore the full Weissenberg WeiFlex Plastic Sheet Bending Machine Series

to see how our solutions support global projects in chemical storage, water treatment, aquaculture, and more.