Plastic Sheet Butt Welder | How to Weld 50 mm Hollow Panels

- Share

- Issue Time

- Aug 22,2025

Summary

Weissenberg specializes in plastic sheet welding, offering reliable Plastic Sheet Butt Welders and global support. The Weibond series is used in chemical tanks, electroplating baths, scrubber systems, aquaculture, and construction panels. With advanced heating, clamping, and traceability, we meet demands for welding solid sheets and 50 mm hollow panels (e.g., Paneltim). Backed by engineering expertise, Weissenberg ensures efficient, stable, and traceable production.

Page Summary (with key equipment parameter)

For PP/HDPE fabrications such as chemical tanks, electroplating baths, scrubber systems, construction panels, and aquaculture tanks, a Plastic Sheet Butt Welder is the preferred solution for butt welding 50 mm Hollow Panels (twin-wall, e.g., Paneltim). Our line supports an effective clamping opening of 63 mm, enabling stable clamping and pressing. Always finalize temperature/pressure/time via on-site welding parameters validation.

1. Why Butt Welding for Plastic Sheets (PP/HDPE twin-wall)?

Compared with mechanical fastening, butt welding/butt fusion (often called heat welding plastic sheet) delivers base-material-like strength, liquid-tight sealing, corrosion resistance, and repeatable quality—critical for PP/HDPE tanks, scrubber systems, and aquaculture tanks. This is why buyers looking for a plastic sheet welder or a welding polyethylene sheet solution choose plastic sheet butt welding for 50 mm Hollow Panels (Paneltim).

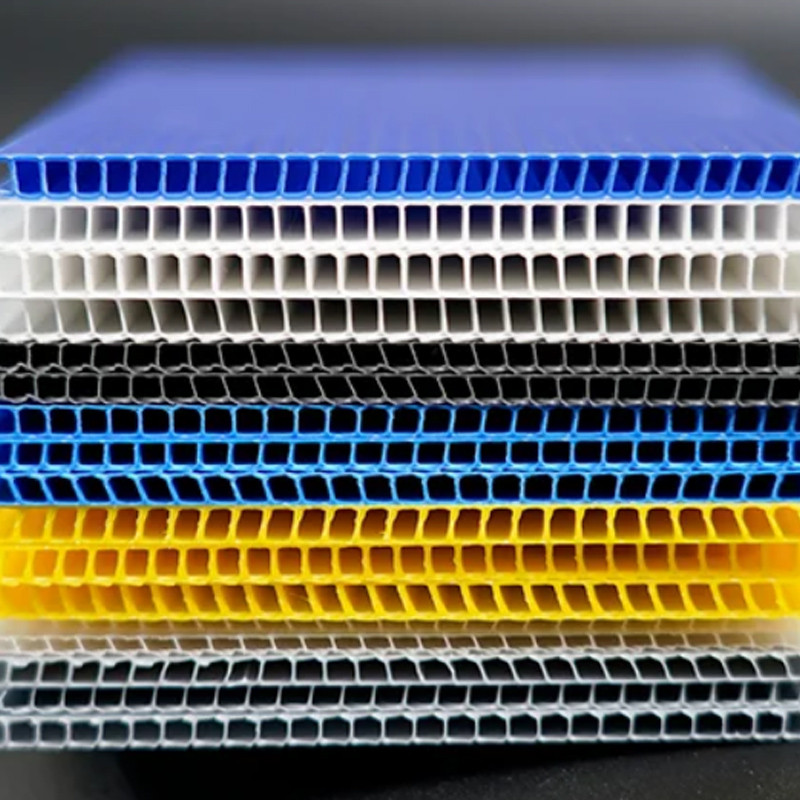

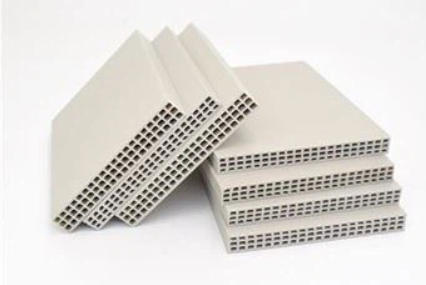

2. Solid vs. Hollow Panels: What Changes in Welding?

Solid sheets (3–30 mm) conduct heat faster and offer a wider window.

Hollow Panels (twin-wall, 50 mm) are light yet stiff; slower heat conduction and internal cells skew heat distribution.

Risks: uneven fusion, contamination, poor airtightness.

They are more sensitive to heating time, temperature stability, clamping, and alignment, so your plastic sheet welding machine must be configured for twin-wall panel welding.

3. SOP for Welding 50 mm Hollow Panels (Paneltim, PP/HDPE)

Validate on your line. Useful starting ranges: PP ~200–230 °C; PE ~190–210 °C. Narrow to your site-specific window after trials.

1) Preparation / Pre-treatment

Saw/plane edges; remove contamination/oxidation; keep edges square.

Check cell orientation; weld open side to open side.

Set clamping opening to 62–63 mm (tune for pad thickness) so parts load smoothly with sufficient stroke for pressing.

2) Clamping & Heating

Use a Plastic Sheet Butt Welder / PP sheet welding machine with an effective 63 mm opening; ensure parallel guides and accurate alignment.

Fit a wide heater bar (~80–85 mm) so skins and web transitions soften uniformly—essential for twin-wall butt welding.

Heat to the validation start; hollow panels usually need longer than solid sheets.

Keep the heater temperature stable and the edges softening synchronously.

3) Pressing & Cooling

Remove the heater and press immediately and smoothly, maintaining uniform pressure and alignment until the bead forms.

Keep clamped during cooling to prevent spring-back/mismatch; reinforce corners/holes afterward with extrusion welding or hot-air welding (same material).

4) Finishing & QC

Trim bead/flash; check seam symmetry and straightness (target mismatch ≤0.5–1.0 mm).

For liquid/pressure service, perform leak/pressure tests; do destructive sampling as required.

Document temperature, pressure, time, material batch, ambient, machine ID, and operator—build traceable records.

4. Weissenberg Case: Weibond 1500 (Solid vs. Hollow Use)

Solid sheets (standard) — 3–15 mm; fast heat conduction, uniform bead; stable mass production on standard settings.

Hollow panels (50 mm, engineered) — Raised fixtures provide a 63 mm effective opening; a ~85 mm wide heater covers skins and web transitions.

Result: uniform butt-welded seams on 50 mm Paneltim; strength and sealing meet engineering requirements after trials/inspection.

5. Equipment Selection for Hollow Panels (50 mm)

Clamping opening/stroke: 63 mm effective opening proven adequate for 50 mm Hollow Panels.

Wide Heating Plate: ~80–85 mm for uniform softening of skins and web transitions.

Alignment + force/position control: minimize mismatch and weak fusion.

Temperature + takt control: stable plate temperature and digital timing/alerts to replicate the window.

Data traceability: export/print parameters for QA audits.

Expandable tooling: 90° fixtures, corner reinforcement, edge-covering stations for extrusion/hot-air work.

6. Quality Control & Documentation

Visual/Geometric: symmetric bead, no charring/voids; straightness/flatness within tolerance.

Functional: leak/pressure tests for tanks and scrubber systems; witness tests if required.

Validation: define your window by small test welds for PP/HDPE and cell formats (50×50 / 50×100).

Records: temperature/pressure/time, material batch, ambient, machine ID, operator; include pad thickness, clamping opening 63 mm, pressing stroke/force, cooling time.

Pre-shift checklist — Opening 63 mm unloaded; re-measure after pads; heater insertion/removal without scraping; compare thin vs thicker pads; target mismatch ≤0.5–1.0 mm; bind parameters and test results to the work order.

7. FAQ

Q1: Which joint method is best for 50 mm Hollow Panels?

A: Mirror butt welding for the main seam; use extrusion/hot-air to cover corners, openings, or reinforcements.

Q2: Are there universal temperatures for PP/HDPE?

A: No. Start at PP 200–230 °C / PE 190–210 °C and refine by equipment, environment, and takt.

Q3: Is a 63 mm clamping opening enough for a Plastic Sheet Butt Welder?

A: Typically, yes for 50 mm twin-wall (Paneltim). If pads are thick or edges warped, optimize pad thickness and edge straightness, then confirm via trial setup/welds.

Weissenberg provides end-to-end solutions for plastic sheet welding:

Plastic Sheet Butt Welder systems (for PP/HDPE), plus extrusion and hot-air stations, and bending.

Engineering options include :

wide heater bars (~85 mm), 63 mm clamping openings (raised fixtures), alignment and force/position control, and data traceability. We support test-weld validation, training/installation, spares, and remote service.