What Is The Maximum Output Of The Extrusion Welder?

- Share

- Issue Time

- Apr 22,2025

Summary

Extrusion welding machines are crucial for production efficiency and weld quality, with output ranging from 1.5 to 3.6 kg/h depending on filler wire diameter. Key factors include wire size, material properties, temperature control, and feed system. Advanced machines feature dynamic output adjustments for optimal welding. Weissenberg’s welders offer precision, stability, and durability, supporting various materials with innovative technology trusted globally.

As a critical piece of equipment in modern welding processes, the output performance of extrusion welding machines significantly influences production efficiency and weld quality. Maximum output capacity is one of the key parameters for evaluating equipment performance, and a proper understanding and control of this parameter are essential for optimizing welding processes.

Output Performance Parameters of Extrusion Welding Machines

Standard Output Range

According to experimental data and industrial practice, the typical output range of extrusion welding machines is:

- Minimum output: 1.5 kg/h (with φ3 filler wire)

- Maximum output: 3.6 kg/h (with Φ4 filler wire)

This range reflects the performance of the equipment under standard working conditions, though actual values may vary depending on the machine model, manufacturer, and operational conditions.

Key Factors Affecting Output Performance

- Filler wire diameter: Output increases proportionally with wire diameter; larger diameters allow higher material output per unit time.

- Material properties: The density, melting point, and flow characteristics of different metals influence actual output.

- Temperature control: The stability and precision of the heating system determine material flow consistency.

- Drive system: The thrust and stability of the wire feed mechanism limit maximum sustainable output.

- Cooling efficiency: Affects the machine's ability to operate continuously under high loads.

Strategies for Optimizing Output Performance

Parameter Matching Principles

To achieve optimal welding results, the following matching principles are recommended:

- Thin-sheet welding: Smaller diameter filler wire (φ3) and lower output (1.5–2.5 kg/h) are preferable.

- Thick-plate welding: Larger diameter filler wire (Φ4) and higher output (3.0–3.6 kg/h) can be used.

- Special materials: Output rates should be adjusted appropriately based on material properties.

Dynamic Adjustment Technology

Modern advanced extrusion welding machines are typically equipped with dynamic output adjustment systems that automatically regulate output based on:

- Weld seam tracking feedback

- Real-time temperature monitoring

- Variations in welding speed

- Differences in material thickness

Case Studies

Automotive Manufacturing Application

In an automotive chassis welding line, the use of Φ4 filler wire and an output setting of 3.2 kg/h increased welding efficiency by 22% while ensuring weld strength met ISO 15614 standards.

Aerospace Application

For welding aluminum alloy aircraft components, the use of φ3 filler wire and precise output control at 1.8 kg/h achieved excellent weld quality and mechanical properties, complying with AS9100 standards.

Maintenance and Calibration Recommendations

To ensure extrusion welding machines maintain optimal output performance, the following practices are recommended:

- Monthly inspection of wire feed mechanism wear

- Quarterly calibration of the temperature control system

- Regular replacement of worn extrusion wheels and guide components

- Maintaining efficient cooling system operation

Conclusion

The maximum output performance of extrusion welding machines is a crucial factor in equipment selection and application. By appropriately selecting filler wire diameter, optimizing process parameters, and performing regular maintenance, the full potential of the equipment can be realized, improving production efficiency while ensuring weld quality. Future developments may include more precise output control systems and the application of adaptive adjustment algorithms.

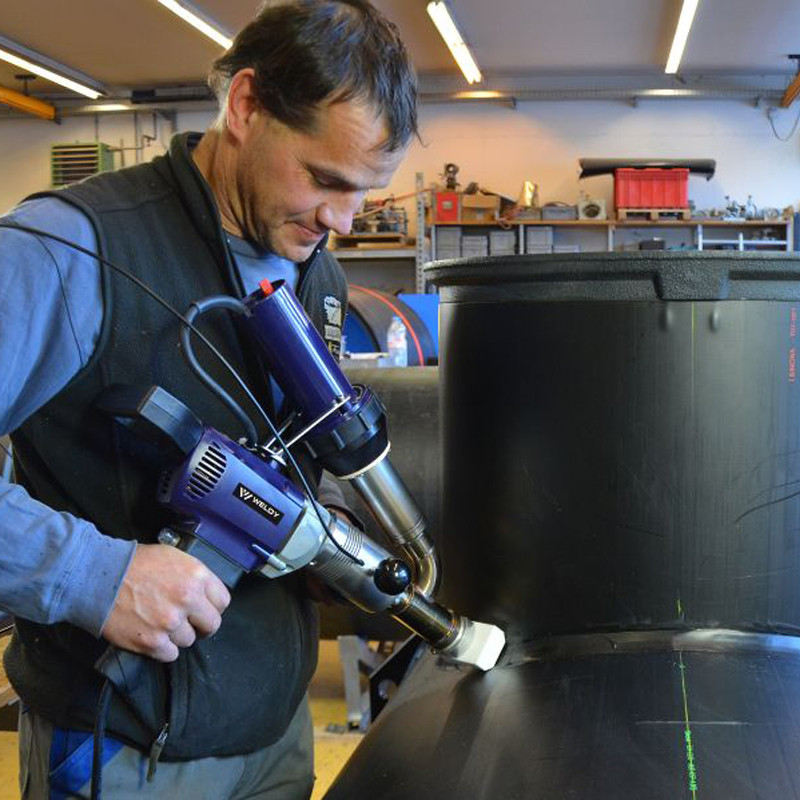

About Weissenberg Extrusion Welder

Weissenberg is a globally renowned manufacturer of industrial welding equipment, specializing in the research, development and production of high-performance extrusion welding machines. With strong technical expertise and innovative capabilities, the brand has established an excellent reputation in the welding industry. Weissenberg extrusion welders are celebrated for their outstanding welding precision, exceptional operational stability and superior equipment durability, meeting the most demanding industrial welding requirements.

Regarding applications, Weissenberg extrusion welders demonstrate remarkable versatility, perfectly suitable for welding thermoplastics (such as PE, PP, PVC), joining various composite materials (including fiberglass and carbon fiber reinforced materials), as well as welding special metal materials (like aluminum and magnesium alloys). The equipment adopts a modular design concept, allowing flexible configurations to ensure stable and reliable welding quality across diverse challenging working conditions.

Weissenberg consistently prioritizes technological innovation. Its extrusion welders integrate advanced temperature control technology, precise wire feeding systems and intelligent operation interfaces, providing efficient and reliable solutions for industrial welding applications. These features have earned the trust and high praise from customers worldwide.