Is Plastic Welding Stronger Than Glue?

- Share

- Issue Time

- May 7,2025

Summary

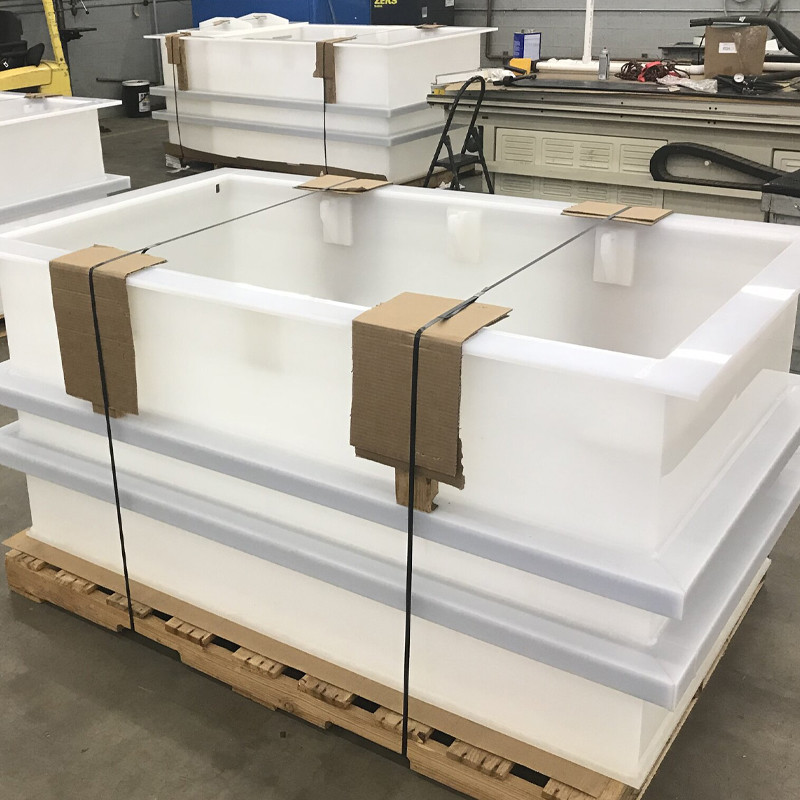

This article compares plastic welding and adhesive bonding, covering performance and applications. Welding offers 80%-100% strength for similar plastics, while adhesives suit dissimilar materials with 30%-50% strength. New trends include laser-assisted bonding and nano-adhesives. Weissenberg machines provide precise, durable welding solutions for industries like plating tanks and spray towers.

In modern industrial manufacturing and daily maintenance, the choice of methods for joining plastic components is crucial. As two mainstream processes, plastic welding and adhesive bonding each possess unique advantages and application scenarios. This article will provide an in-depth analysis of the performance characteristics, applicable conditions, and practical application cases of these two technologies to assist you in making informed decisions.

Comparison of Strength Performance

Plating Tanks[/caption]

Plating Tanks[/caption]

Plastic welding involves melting the contact surfaces, which then cool to form a molecular-level fusion. This type of joint typically achieves 80%-100% of the base material's strength. For example, polypropylene (PP) pipes joined through hot plate welding demonstrate burst pressures nearly identical to those of the original pipe material.

In contrast, adhesive bonding relies on the adhesion between the glue and the plastic surface. Even with high-performance structural adhesives, bond strength generally reaches only 30%-50% of the base material's strength.

Regarding long-term durability, welded joints exhibit superior resistance to environmental stress. Automotive industry tests show that under thermal cycling conditions (-40°C to 85°C), welded joints endure 3-5 times more cycles before failure compared to adhesive bonds. For components subjected to vibration or impact—such as motorcycle plastic housings—welded connections demonstrate even greater advantages.

Material Compatibility and Application Scenarios Analysis

Plastic welding is particularly suitable for joining homogeneous thermoplastic materials. Commonly weldable plastics include:

• Polypropylene (PP)

• Polyethylene (PE)

• Polyvinyl Chloride (PVC)

• Acrylonitrile Butadiene Styrene (ABS)

Welding is the preferred process in these scenarios:

- Load-bearing structural components: e.g., industrial plastic pallets, amusement equipment parts

- High-sealant-required applications: Chemical containers, water supply pipelines

- High-temperature environments: Plastic components in automotive engine compartments

Adhesive bonding is more suitable for:

- Dissimilar material joining: e.g., bonding ABS plastic to metal frames

- Precision or micro components: Plastic clips in electronic devices

- Temporary or detachable connections: Exhibition props, experimental setups

Typical Industry Application Cases

- Automotive Manufacturing:

- Welding Applications: Front/rear bumpers, dashboard frames (ultrasonic welding)

- Adhesive Applications: Roof moldings, door panel trims (polyurethane structural adhesive)

- Electronics & Electrical Appliances:

- Welding Applications: TV housings (vibration friction welding)

- Adhesive Applications: Smartphone frames and screen bonding (UV-curing adhesive)

- Pipeline Engineering:

- Welding Requirement: Polyethylene gas pipes must use electrofusion welding (industry standard)

- Adhesive Solution: PVC drainage pipe repairs (temporary emergency fixes with specialty adhesives)

Innovation Development Trends

Modern manufacturing is advancing with hybrid joining technologies:

- Laser-Assisted Adhesive Bonding: Initial adhesive positioning followed by localized laser heating to enhance bond strength

- Microwave Welding: Selective heating for plastics containing special additives

- Nano-Modified Adhesives: Carbon nanotube-enhanced formulations for improved conductivity and strength

These emerging technologies demonstrate distinct advantages in specialized applications. For instance, laser-assisted joining in medical device manufacturing combines adhesive precision with near-welding strength performance.

Selection Guidelines

For professional users, we recommend the following decision-making process:

- Define operating conditions (temperature, humidity, load requirements, etc.)

- Confirm material type (weldability assessment)

- Evaluate production volume

- Consider maintenance needs

For DIY enthusiasts, adhesives often present a more practical solution. Modern plastic adhesives like cyanoacrylate (instant glue) or epoxy resins can adequately address most household repair needs.

Conclusion

Both plastic welding and adhesive bonding have distinct merits with no absolute superiority. As material science advances, both technologies continue to evolve. Professional engineering evaluation is recommended for critical components. For everyday applications, the guidelines presented herein provide a reliable reference. Proper joining method selection ensures operational safety, extends product lifespan, and optimizes total cost of ownership.

Weissenberg Plastic Sheet Welding Machines: Precision Engineering for Industrial Excellence

Discover our premium range of Weissenberg Plastic Sheet Welding Machines, engineered for superior performance in demanding industrial environments. We offer an extensive selection of models with working widths from 1500mm to 7000mm, designed to meet the exacting requirements of professionals across multiple industries.

Our high-performance welding systems are ideally suited for:

- Electroplating tank fabrication

- Spray tower construction

- Wastewater treatment systems

- Chemical processing equipment

Key advantages of Weissenberg welders include:

- Unmatched precision for flawless seams

- Robust construction for industrial durability

- Customizable configurations for specialized applications

For unique project requirements, our engineering team can develop bespoke plastic sheet butt welders tailored to your specific needs. Contact our sales specialists today to find your perfect welding solution.